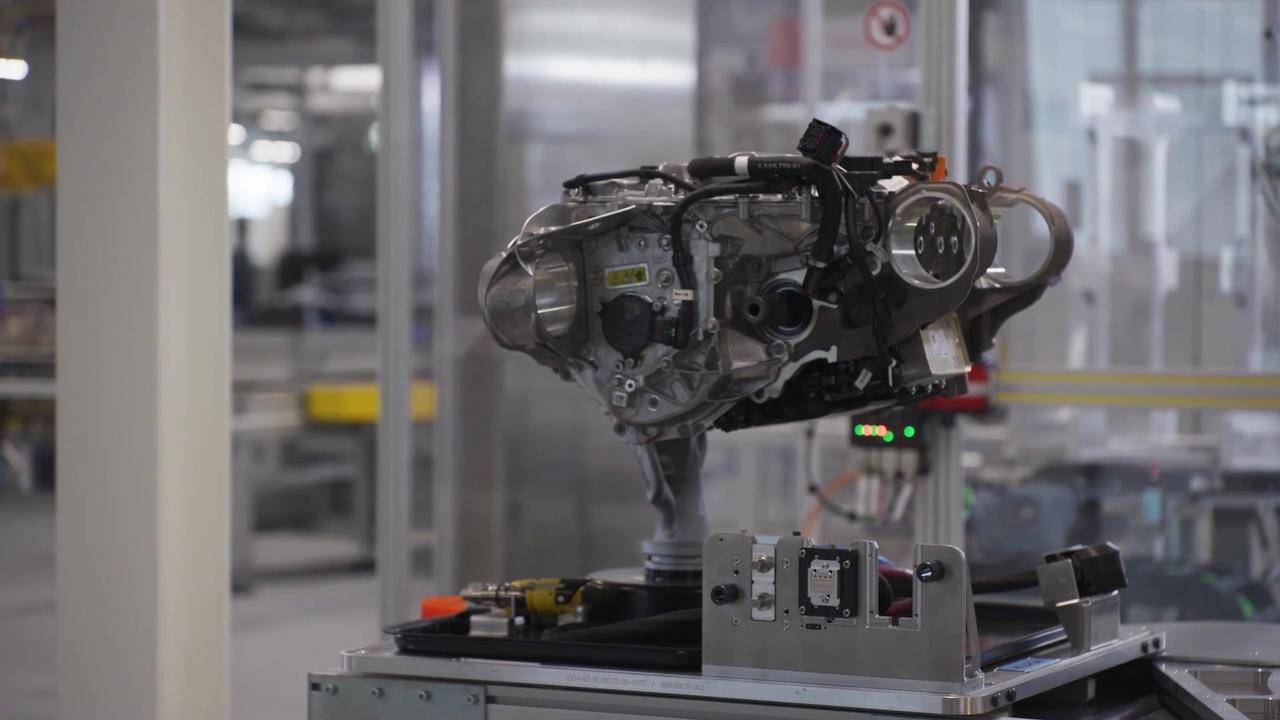

Rotor, stator, transmission and inverter – all core components of the innovative, highly integrated e-drive – will be manufactured at Plant Steyr.

The housing for the electric engine will be cast at Plant Landshut's aluminium foundry and further processed in Steyr.

The inverter will be produced in a new in-house clean-room environment, marking the Austrian engine manufacturer’s entry into the field of electrical engineering.

E-drive components from Steyr will be assembled on two new lines.

The overall production concept for the Gen6 e-drive follows the principle of a modular system, making it possible to produce different highly flexible electric drive train derivatives for the entire range of Neue Klasse models.

The modular concept generates positive economies of scale and cost savings in both development and production.

It also improves the scalability of production volumes and keeps production, supply networks and procurement highly flexible.